Prefabricated Houses: A Practical Guide to Types, Costs, and Buying Considerations

Outline:

– What prefab means and the major categories

– Cost breakdown and value drivers

– Design, materials, and performance

– Permits, site prep, logistics, and timeline

– Buying checklist and conclusion

What Prefab Really Means: Types and How They Work

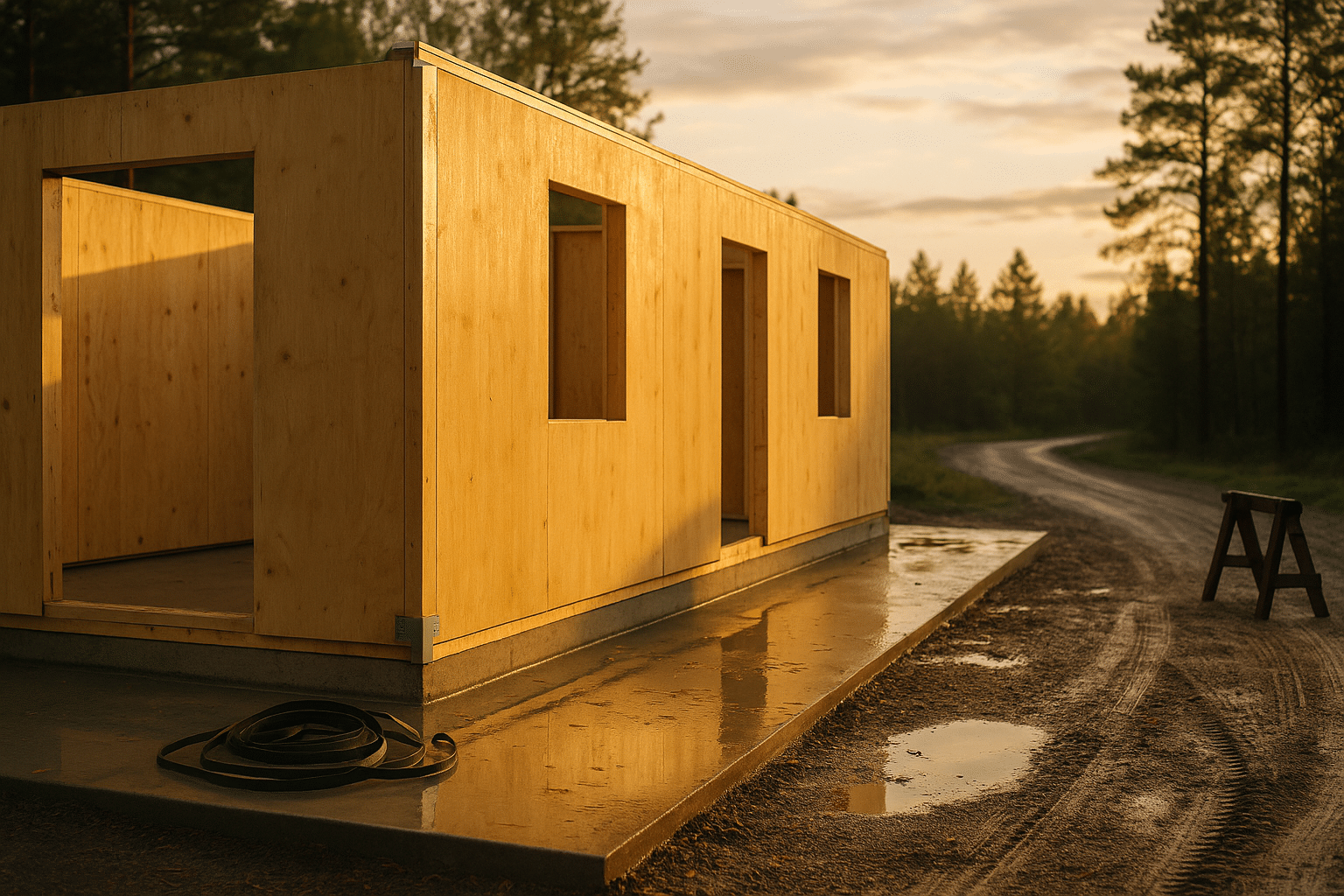

“Prefab” is a shorthand for homes built partly or mostly in a factory and then transported to a site for assembly. The idea is simple: shift construction into a controlled environment where weather delays shrink, quality checks are consistent, and materials are safeguarded. Yet prefabrication is not one single thing; it’s a spectrum of methods that range from flat wall panels delivered to a slab, to fully finished modules craned into place like building blocks. Understanding the categories helps you compare apples to apples when you review proposals.

Common types you’ll encounter include:

– Modular (volumetric): Three-dimensional boxes built to local building codes, often 70–90% complete at the factory, then set on a permanent foundation and finished on site.

– Panelized: Walls, floors, and roof systems arrive as panels; a local crew assembles them, then completes mechanicals and finishes.

– Manufactured: Built to a national code, typically transported on an integrated chassis; can be installed on piers or a permanent foundation depending on local rules.

– Kit or component homes: Bundles of pre-cut materials with detailed plans; assembly is more site-intensive but streamlined compared to fully custom builds.

These approaches share a manufacturing mindset, but they deliver different experiences. Modular homes, for example, often compress the onsite timeline dramatically because most finishes—drywall, cabinets, flooring—are completed under the factory roof. Panelized systems speed framing and enclosure, making it easier to hit airtightness and energy targets, while still leaving room for local customization. Manufactured homes reduce cost barriers for buyers who need a straightforward, code-compliant dwelling, and in certain areas they can be placed in communities zoned specifically for that housing type.

Key differences show up in codes and financing. Modular and panelized homes are inspected to the same local codes as site-built houses, which generally means mainstream permitting and conventional financing paths. Manufactured homes follow a separate national standard and may face different zoning and lending requirements; resale dynamics can also vary by market and by whether the home is on leased land or a permanent foundation. No method is universally superior; each is a tool with a target use case. The right fit depends on your site, budget, timeline, and appetite for customization. Think of prefab as a toolkit: the craft lies in choosing the right components to match your goals, not in forcing a single approach onto every project.

Costs and Value: Budgeting Without Surprises

Prefab is often associated with savings, but the real value is predictability. Factory scheduling reduces weather downtime and rework, which can stabilize costs. Still, the line items are broader than the “base house” quote, so a transparent budget is essential. A practical way to plan is to combine per-square-foot ranges with a detailed checklist of extras your project will require.

Typical price ranges vary widely by region and specification:

– Manufactured homes: roughly $50–$110 per square foot for the home itself, with installation costs on top.

– Panelized and modular: roughly $120–$250 per square foot depending on finishes, energy targets, and complexity.

– Conventional site-built often overlaps and can exceed these ranges in high-cost markets.

These figures are illustrative, not guarantees; land, labor, and code requirements can shift totals significantly.

Beyond the factory price, include:

– Land and due diligence: surveys, soil tests, environmental screens.

– Design and engineering: plan customization, structural calculations, energy modeling.

– Permits and fees: local submittals, impact fees, utility connection charges.

– Transportation and set: module or panel delivery, route escorts if needed, crane days.

– Foundation and site work: excavation, concrete, drainage, driveways, grading.

– Mechanical and finishes: HVAC, plumbing tie-ins, electrical service, interior punch list.

– Contingency: 10–15% to handle surprises like rock excavation or utility upgrades.

Life-cycle economics matter as well. Factories can reduce material waste substantially by optimizing cuts and reusing offcuts, which is both cost-conscious and resource-friendly. Many modular and panelized homes achieve tighter envelopes and more consistent insulation, which can lower heating and cooling loads; in colder climates, that might translate to double-digit percentage reductions in energy use relative to older, draftier stock. A shorter build schedule may also cut interest carry on construction loans and reduce rental overlap if you’re moving from another home. Resale value depends on local perception and quality: homes built to local codes with durable finishes and strong energy performance tend to appraise competitively because they function like any well-constructed house—they just originated in a factory.

Design, Materials, and Performance: Getting the Home You Want

Modern prefab sheds the cookie-cutter stereotype. Because modules and panels are engineered precisely, they can support open floor plans, large windows, and energy-smart envelopes without heroic measures. The factory setting favors repeatable quality: cuts are straight, components are stored dry, and assemblies are inspected at each station. The result can be a quiet, comfortable shell that performs consistently across seasons.

Materials vary by builder and climate. Light-frame wood remains common for walls and floors due to its cost-effectiveness and predictable behavior. Steel framing appears in certain systems where long spans or high strength-to-weight ratios are needed. Engineered wood products and cross-laminated panels can offer excellent dimensional stability and speed. Insulation options range from dense-packed cellulose and fiberglass batts to continuous exterior foam or mineral wool. Many energy-conscious builds target:

– Wall assemblies in the R-21 to R-30 range, adjusted for climate zone.

– Roof/ceiling insulation from R-38 to R-60, especially in cold regions.

– Airtightness in the vicinity of 1.5–3.0 ACH50 when detailed carefully.

Numbers vary, but these ballparks show what’s achievable with attention to the envelope.

Performance is more than insulation. Good windows with low U-factors and sensible solar heat gain coefficients can tame seasonal swings. Air-sealing at module seams or panel joints is crucial; gaskets, tapes, and fluid-applied membranes help create a continuous barrier. Ventilation is the quiet hero: balanced systems with heat or energy recovery keep indoor air fresh while conserving warmth or coolth. For durability, details like rainscreens, robust flashing, and moisture-tolerant materials in wet zones pay dividends. In windy or seismic regions, modular homes often benefit from redundancy: modules act like rigid boxes, tied together with straps, bolts, and engineered connectors designed to distribute loads. Fire-resistance strategies include Type X gypsum, mineral wool, and defensible space landscaping where applicable.

Design choice remains abundant. You can select finishes that suit your taste—matte or textured exteriors, warm wood interiors, polished concrete, or resilient plank flooring—without breaking the fabrication logic. Creativity shines when you align architecture with the manufacturing grid: stack modules for multistory living, or rotate them to shape courtyards that harvest light and privacy. Done thoughtfully, prefab becomes a choreography of parts that feels effortless—like a jazz ensemble where every instrument knows its cue.

Permits, Site Prep, Logistics, and Timeline: From Paper to Keys

Every successful prefab project starts with local rules. Zoning dictates what you can build, how big it can be, and where it sits on the lot. Building departments review structural, energy, and life-safety compliance; modular and panelized homes are typically permitted like any site-built residence. Manufactured homes may follow separate placement rules, and some jurisdictions designate specific parks or require permanent foundations. Before you fall in love with a plan, verify setbacks, height limits, parking requirements, and utility availability.

Site prep is where budgets stay on track—or drift. A geotechnical review can reveal bearing capacity, groundwater, and frost considerations that inform foundation type. Common foundations include slabs-on-grade, crawlspaces, and basements, each with pros and trade-offs. Utilities must be planned early: electrical service sizing, water supply or well capacity, sewer or septic design, and any special requirements for fire flow or backflow prevention. Driveway geometry, turning radii, and overhead clearances matter because trucks delivering modules or panels are long, tall, and not fond of tight corners.

Logistics deserve their own spotlight:

– Transportation: Oversize loads may require permits, escorts, and specific travel windows.

– Set day: Cranes need stable ground, clear swing paths, and wind-safe conditions; weather buffers are wise.

– Sequencing: Coordinate foundation cure times, utility stubs, and inspections so the set proceeds smoothly.

– Protection: Temporary coverings and careful sealing at seams keep weather out until final finishes are complete.

Timelines vary, but a reasonable framework looks like this:

– Pre-design and budgeting: 2–4 weeks to align scope and ballpark costs.

– Design and engineering: 2–8 weeks depending on complexity and approvals.

– Permitting: 2–12 weeks, highly dependent on local load and review cycles.

– Factory fabrication: 2–8 weeks, with parallel site prep whenever possible.

– Delivery and set: 1–3 days for modules, longer for panelized assemblies.

– Onsite finish: 2–8 weeks for mechanicals, exterior trim, and punch items.

When phases overlap intelligently, total duration from greenlight to move-in can fall in the 8–24 week range, but small delays compound. Building a buffer into both schedule and budget is not pessimism; it’s prudence.

Risk management is the quiet superpower of prefab projects. Secure route surveys early for tricky sites. Confirm that your contract assigns responsibility for cranes, traffic control, and weather contingencies. Schedule pre-set meetings to walk through safety, sequencing, and protection of finished surfaces. The smoother the choreography, the sooner you’ll be planning a housewarming.

Smart Buying Checklist and Conclusion: Confidence from First Call to Final Walkthrough

Choosing a prefab path is really about choosing partners and a process. A good starting point is to interview multiple providers with the same brief and ask them to price the same scope; comparable quotes reveal value drivers clearly. Request sample contracts, warranty terms, and a schedule of allowances for finishes and fixtures. If possible, tour a factory and a completed home of similar specification to gauge fit and finish, weather protection protocols, and site coordination habits.

Key checklist items for buyers:

– Scope clarity: What is included in the base price and what is excluded?

– Engineering responsibilities: Who stamps drawings for local submission?

– Logistics: Who handles transport permits, route surveys, and crane operations?

– Site work: Which party manages foundation, utilities, grading, and inspections?

– Schedule: What milestones are contractual, and what are the remedies for delays?

– Quality: What are the airtightness, insulation, and window targets?

– Warranty and service: Who resolves punch-list items and how quickly?

– Change management: How are design changes priced and approved?

Financing deserves early attention. Many lenders offer construction-to-permanent loans that fund the build and then convert to a standard mortgage after completion. Appraisals rely on comparable sales; modular and panelized homes built to local codes typically appraise alongside site-built counterparts of similar quality. Manufactured homes can appraise differently depending on land ownership, foundation type, and community norms, so align expectations with local professionals.

Maintenance and long-term value hinge on the same principles as any durable house: keep water out, control indoor humidity, and service mechanical systems on schedule. Because modules and panels tend to be built straight and dry, they set a strong baseline—sustain that with careful detailing at joints, appropriate sealants, and regular inspections of roof, cladding, and penetrations. If energy performance was a goal, document blower-door results, insulation levels, and equipment specs for future owners; transparency supports appraisals and resale confidence.

In closing, prefabricated houses offer a practical path to a well-made home with fewer unknowns and a schedule you can plan around. They are especially appealing to first-time buyers who value cost clarity, downsizers seeking efficient layouts, rural landowners facing long distances for trades, and urban infill projects constrained by tight sites. If you map your goals, compare methods thoughtfully, and choose partners who are candid about scope and risk, prefab can turn an abstract dream into a grounded, livable reality—one truckload at a time.